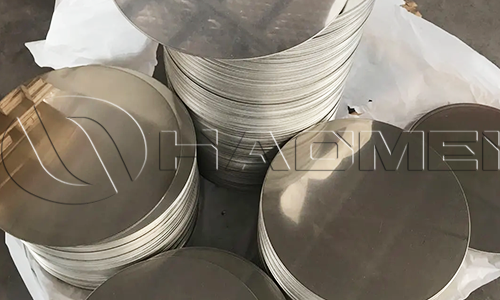

Aluminium circles a 1050 for cookware

April 2, 2021

Aluminium circles a 1050 is a popular material for cookware. The name of A1050 is registered by Japan, roughly equal to 1050 by America. The alloy contains 99.5% aluminum and 0.5% other metals. It is light, tensile, corrosion resistant, heat conductive, safe and cheap, and is an ideal material for cookware.

The softness of aluminium is second only to Magnesium. The highly alu content of aluminium a1050 makes it one of the softest alloys of all. The tensile strength of 1050 is excellent, too, so it’s suitable for deep drawing and spinning. The corrosion resistant of pure aluminium proves to be good, for a thin film of oxide aluminium comes into being on the aluminium circle surface. Although the thickness of this film is uneven, it can be improved by anodizing or color coating. Thin as it is, this film keeps most corrosive materials which cookware might contact outside. In this way the service life of a cooker or pot extended. The heat conductivity of 1050 aluminum circle is better than steel, second only to copper in regular cookware metals.

The most advantageous of all, lies in the high cost efficiency of aluminium circles a 1050 in comparison to circles of other aluminum alloys and metals. The current manufacturing technology and process are quiet mature for 1050 sheet rolls and circles, which results in rising of number of manufacturers and drop in price. In spite of this, purchasers should be careful in choosing suppliers. No matter how cheap a product is, there will always be difference in quality. Thus choosing an experienced supplier is a better choice.

Nydia

Nydia

Sales Manager

Sales Manager