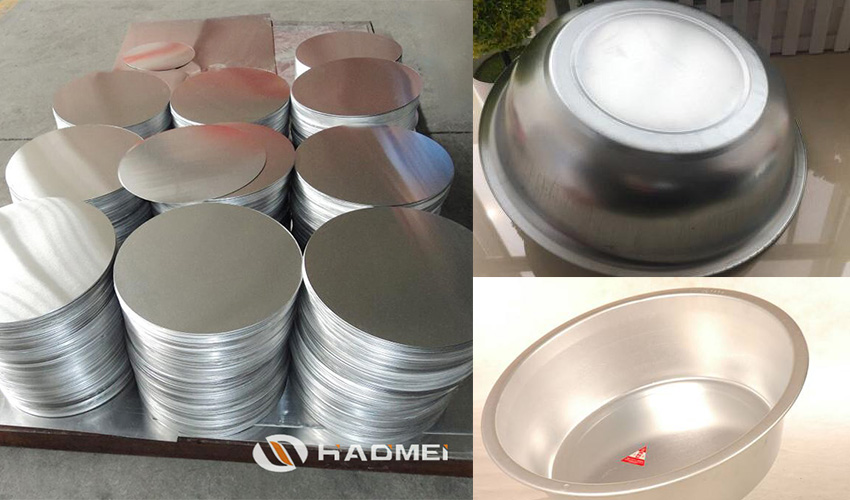

Big aluminium circle for basins

March 3, 2020

Aluminium circle big /aluminum disc plates are used as raw materials for basins because of their light weight, good corrosion resistance, medium strength and low comprehensive cost. They are also known as aluminum wafers or aluminum round sheets. Frequently applied alloys are 1050, 1060, 1070, 1100 and 3003. They cover a wide range of application in our daily life, like pots, kettles, cookers, basins, bowls, lighting covers etc. In previous articles we have discussed aluminum circles used in cookware, but it proves to be a little difficult to place basins in this classification, because basins have a usage scope far beyond cookware.

In the past there were small basins made of small spining circle aluminum plates, and they were used as dish or soup containers. Big basins are more popular now, they are usually thick and heavy, used as washing basins in the countryside. Aluminum basins prove to be strong, light and long lasting. They are much stronger than plastic basins that would get broken or cracking after sunshine or heavy shocks. Of course, they are heavier than plastic basins, but much lighter than basins of other metals which are suitable to be made into basins, mostly copper and steel. Owing to the fact that circle aluminum plates are corrosion resistant, the basins last a long time without getting out of service. Because of good tensile strength of aluminum discs, the basins might get potted with small calderas which do not affect the normal using at all. Last but not least, aluminium circle big /aluminum disc sheets prove to be cheaper as raw materials for containers like basins, because they have a small density and lower integrated price in comparison with other metals.

Nydia

Nydia

Sales Manager

Sales Manager