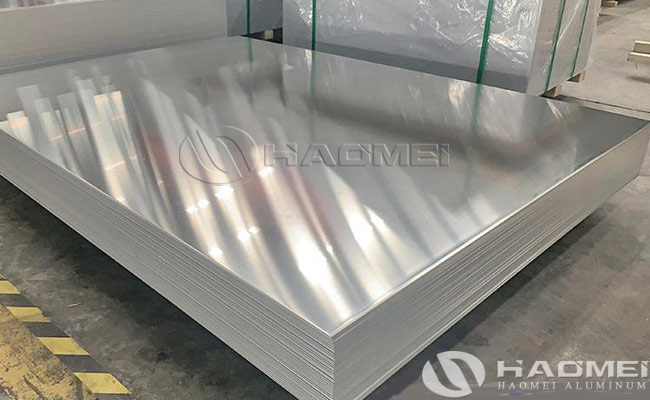

Aluminium Alloy 6082 T6

September 18, 2023

Aluminium alloy 6082 t6 is a medium-strength alloy with excellent corrosion resistance. It is the strongest alloy in the 6000 series. Alloy 6082 t6 is known as a structural alloy. In sheet form, t6 6082 is the most commonly used alloy for machining. As a relatively new alloy, its higher strength has replaced 6061 aluminium in many applications. The addition of a large amount of manganese can control the grain structure, thereby producing a stronger alloy.

It is difficult to produce thin-walled, complex extrusion shapes in aluminium alloy 6082 t6. The surface finish of extrusions is not as smooth as other similar strength alloys in the 6000 series aluminum. In the T6 and T651 states, aluminium alloy 6082 machines well and produces tight chip curls when using chip breakers.

Applications of 6082 aluminium plate:

Aluminium alloy 6082 is commonly used for:

– High-stress applications

– Trusses

– Bridges

– Cranes

– Transportation applications

– Ore machines

– Beer barrels

– Milk stirrers

Chemical Composition of 6082 t6:

Specification: BS EN 573-3:2009

Alloy 6082

Chemical Element % Present

Manganese (Mn): 0.40 – 1.00

Iron (Fe): 0.0 – 0.50

Magnesium (Mg): 0.60 – 1.20

Silicon (Si): 0.70 – 1.30

Copper (Cu): 0.0 – 0.10

Zinc (Zn): 0.0 – 0.20

Titanium (Ti): 0.0 – 0.10

Chromium (Cr): 0.0 – 0.25

Other (each): 0.0 – 0.05

Other (total): 0.0 – 0.15

Aluminium (Al): Balance

Properties of aluminium alloy 6082 t6:

Physical Properties Value

Density: 2.70 grams/cubic centimeter

Melting Point: 555°C

Thermal Expansion: 24 x10^-6 /K

Young’s Modulus: 70 Pa

Thermal Conductivity: 180 W/mK

Electrical Resistivity : 0.038 x10^-6 Ω.m

Nydia

Nydia

Sales Manager

Sales Manager