Product Categories

- Aluminum Coil (49)

- Aluminum Strip (28)

- Aluminum Tread Plate (23)

- Aluminum Foil (13)

- Aluminum Slugs (4)

- Aluminum Sheet (46)

- Aluminum Profile (16)

- Aluminum Circle (21)

- Color Coated Aluminium (22)

- CTP Plates (3)

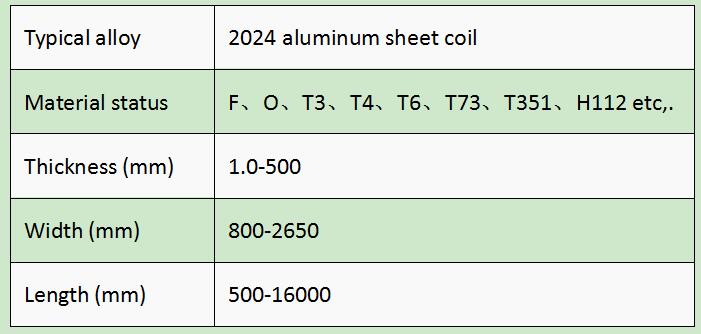

Typical alloy: 2024 aluminum sheet coil

Material status: F、O、T3、T4、T6、T73、T351、H112 etc,.

Thickness (mm): 1.0-500

Width (mm): 800-2650

Length (mm): 500-16000

enquiryTechnical Parameters

Aluminum sheet 2024 is made of an aluminum-copper alloy with high strength-to-weight ratio, used for truck and aircraft wheels, aircraft fusilage components, truck suspension parts and so on. 2024 alloy does have limited weldability, and it is less corrosion resistant than other alloys.

2024 aluminum plate is a typical hard aluminum alloy in the Al-Cu-Mg system, feature by reasonable composition and good comprehensive performance. Required in many countries, 2024 aluminum coil sheet ranks top in demand quantity in hard aluminum. The alloy is characterized by high strength and a certain heat resistance, and can be used as a working part below 150 °C. 2024 aluminum alloy, density is 2.85 g/cm3.

Chemical Composition

Silicon: 0.5% Iron: 0.5% Copper: 3.8-4.9 Manganese: 0.3-0.9 Magnesium: 1.2-1.8 Chromium: 0.10 Nickel:- Zinc: 0.25 Ti: 0.15 Other: 0.15 Aluminium: Remaining

Mechanical Properties

As a kind of high-strength hard aluminum, aluminum sheet 2024 can be heat-treated and strengthened.

Plasticity: medium plasticity in quenching and quenching state

Welding: good spot welding, and there is a tendency to form intergranular cracks during gas welding.

Machinability: good after quenching and cold hardening but low after annealing

Corrosion resistance: low, and anodizing or color coating is often used to improve the corrosion resistance.

2024 aluminum plate is mainly used to make various high-load parts and components (but not stamping forgings) such as skeleton parts, skins, partitions, ribs, spars, rivets and other working parts below 150 °C.