6061 Anodized Aluminum Sheet

April 26, 2024

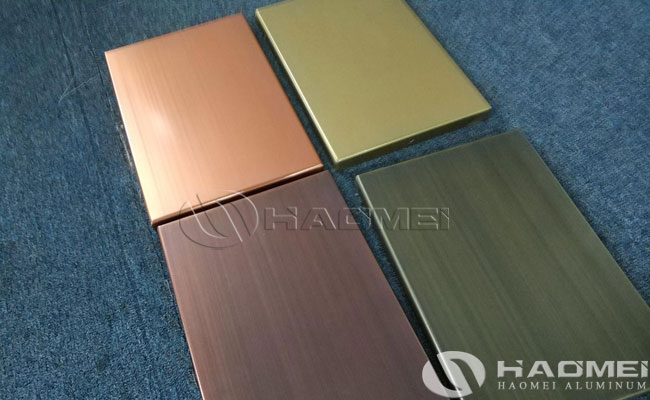

6061 anodized aluminum sheet is 6061 aluminum sheet alloy through anodizing process with an oxidized surface. 6061 anodized aluminum can be processed in thicknesses of 0.2 – 500 mm, with the widest range of 950 – 1800 mm, commonly used tempers are T6 and T651. it can ensure that the thickness of the oxide film is uniform and up to standard.

6061 anodized aluminum sheet is an sheet alloy composed of aluminum, magnesium and silicon, with excellent mechanical properties and processing performance, is widely used in aviation, automotive, construction, electronics and other industries. This aluminum alloy significantly improves the mechanical properties and corrosion resistance of aluminum by adding alloying elements such as magnesium and silicon, as well as small amounts of copper and zinc.

Aluminum 6061 plate has medium strength and good workability, and can be easily cut, bent, drilled and welded. It also has excellent corrosion and oxidation resistance and can be used in harsh environments for long periods of time without damage. In the construction industry, 6061 aluminum sheet is commonly used for decoration and protection of exterior walls, roofs, doors and windows, etc. Its surface can be sprayed, anodized and other treatments to increase its beauty and corrosion resistance.

When 6061 aluminum plate after anodizing treatment, its surface will form a dense layer of aluminum oxide film, further improving its corrosion resistance and hardness. This oxidation treatment can make the surface of the 6061 aluminum plate more beautiful and increase its service life.

In summary, 6061 anodized aluminum sheet with oxidation treatment, not only retains the original excellent performance, but also enhances its surface corrosion resistance and aesthetics, so that it is more advantageous in a variety of applications.

Nydia

Nydia

Sales Manager

Sales Manager