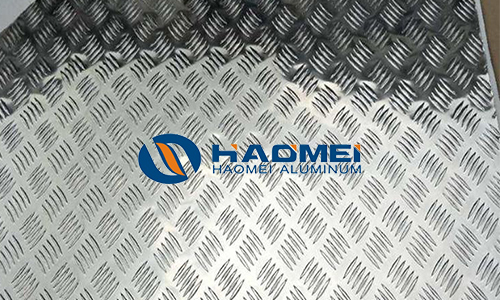

5083 checkered aluminum sheets for car pedals

February 19, 2020

5083 checkered aluminum sheets are promising materials for automotive pedals, meeting requirements of high hardness. The density of aluminum alloys is low, but the strength is relatively high, which is close to or exceeds that of high-quality steel. They overshadow most regularly applied metals with strong corrosion resistance and high plasticity, too. As a result, aluminium alloy sheets become the second adopted metals in the industrial field.

However, not all aluminum alloy plates are sufficiently strong to serve as car pedals. 1xxx and 3xxx sheets, for instance, are excluded from the candidate list because of poor hardness. 5083 aluminum sheet, on the other hand, beat the two series mentioned in either strength or corrosion resistance. 5083 high-quality aluminum plate belongs to Al-Mg-Si series alloy, which is widely used in places requesting high corrosion resistance, good weldability and medium strength, such as ship, automobile and aircraft plate welding parts. What’s more, the performance advantages of 5083 aluminum alloy can add technical content to the production of automotive pedals.

Checkered aluminum sheets used for auto pedals should be around 3mm thick, for the thickness of an aluminum plate affects its hardness and weight bearing ability directly. A piece of 3mm aluminium checker plate of 5083 totally fulfill strength levels needed with pedals. As a pedal serves as an anti-skid unit as well, patterns of the plates must be selected carefully. Generally only five bar and one bar plates are adequate here, for their arrangement and height bring the strongest anti-slip force out of them.

Nydia

Nydia

Sales Manager

Sales Manager