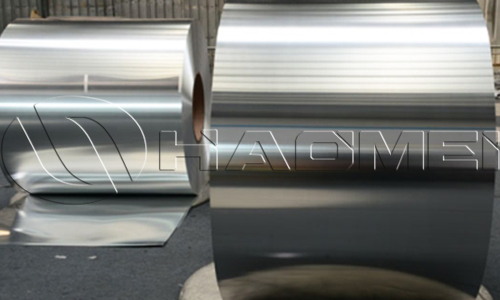

5052 h32 aluminum alloy coils for rolling shutter door

June 8, 2021

5052 h32 aluminum alloy coils are among the most widely applied anti-rust aluminum in Al-Mg series. They have high elongation, strong corrosion resistance and good strength. The coils serve as an outstanding material for shutter doors. They are usually processed by hot rolling, anodizing and even color coating. 5052 aluminum coil belong to the aluminum alloy group of high and medium strength, featured by low density, good plasticity, excellent forming property, easy processing property, strong resistance to marine atmosphere, and higher strength than 1000 and 3000 series of aluminium.

As a rolling shutter door material, 5052 h32 aluminum coil is much stronger in hardness and corrosion resistance than 3003, 3005 and 3105 aluminum alloy coils. It contains magnesium as the alloying metal, making its density even smaller than pure aluminium, for the density of Mg is lower. As a result, 5052 is the among the lightest of all aluminum alloys. In addition, the adding of magnesium improves the anti-oxidation property of aluminium. Aluminium itself displays excellent resistance to oxidation. It’s not that aluminum does not react to oxygen, but that it reacts to the oxygen so quickly that a layer of aluminium oxide comes into being on the surface and acts as a protective film. Different from loose powder oxide of other metals like copper and iron, aluminum oxide is firm and dense, preventing other materials from invading into the inner material.

Haomei 5052 h32 aluminum alloy coils for rolling shutter doors are 0.21mm to 0.6mm thick, and 80mm to 1600mm wide. Thicknesses of 0.21, 0.22, 0.23, 0.25, 0.26, 0.27, 0.3mm are popular, and widths of 118.8, 127, 133, 138, 187mm are popular. The coil rolls are processed by hot rolling. Surface treatment methods like anodizing and color coating are available. The thickness and width of the coils can be customized.

Nydia

Nydia

Sales Manager

Sales Manager