3105 Aluminum Sheet

October 20, 2022

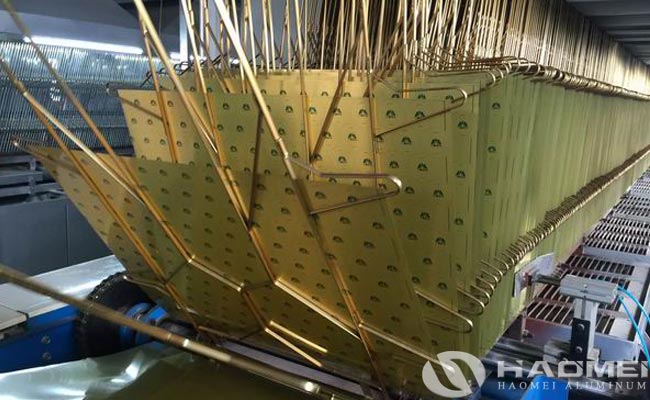

3105 aluminum sheet belongs to 3000 series aluminum-manganese alloy, which has good anti-rust performance and good deep drawing effect. The strength, elongation and processing performance of the 3105 aluminum material meet the production process of automatic bottle caps with high strength, and there will be no creases during processing. or rupture. Moreover, the 3105 aluminum sheet for bottle cap material has a flat shape, no roll marks, and no oil spots, which is convenient for later printing and makes the pattern clear and recognizable.

Aluminum bottle caps are widely used in the packaging of wine, beverages, and bottled medicine because of their good sealing effect and beautiful appearance. Commonly used alloys are 8011 aluminum foil, 3104 aluminum plate, 3105 aluminum sheet, etc. In particular, people pay more and more attention to the anti-counterfeiting of wine. Aluminum bottle caps not only have good printing effect, but also have significantly better performance than plastic bottle caps. They are favored by wine manufacturers, and the market demand is increasing year by year. 3105 aluminum plate is a deformed aluminum alloy with high tensile strength, elongation up to 20%, and good deep drawing performance. It is suitable for thinning, stretching and lightweighting to reduce the amount of materials. The requirements of each process of the tank material are strict, and our company strictly controls it. Various processes, so that the product has suitable strength and formability.

The specification of aluminum sheet for bottle caps are:

Thickness: 0.1-500mm

Width: 100-2650mm

Length: 500-16000mm

3105 aluminum sheet market application: room partitions, baffles, prefabricated home panels, color-coated aluminum substrates, shutters, lamp caps, gutters and downspouts, sheet metal forming parts, bottle caps, bottle stoppers, cake trays, candle holders, tea tins and so on.

Nydia

Nydia

Sales Manager

Sales Manager