3003 aluminum coil for power battery

February 7, 2020

The 3003 aluminum coil is one the most commonly applied aluminum alloy of 3000 series. It contains a large content share of aluminum and little manganese which performs excellent anti-corrosion property. With stronger hardness than 1100 aluminum coil, it shows good workability, high corrosion resistance, satisfying welding property and extraordinary electricity conductivity. This type of aluminum coil can not be hot treated, therefore, its mechanical property is usually improved by cold processing methods. It’s of better plasticity at semi-cold hardening than at full-cold hardening.

The a3003 h16 aluminum coil proves to be the best material for cover of power battery. When we use a mobile phone, what we worry most about is that the phone may break or get damaged in case of occasional falls onto the floor. In the past a cell phone would break into several pieces once dropped onto the ground. The power battery usually got out of the cover which had been pushed off by strong falling shock, and a cover, commonly made of plastics, cracks quickly after several falls. However, it’s a different case now. Almost all power battery covers for cell phones are made of metals, especially 3003 aluminum coil. The coil has super property against shocks. Even though you drop your phone deliberately, it seldom breaks. The first part to be damaged is usually the screen rather than battery cover. Besides, the coil can also be processed into reflective covers for lights and lamps, caps for wine bottles, components for interior decoration, etc. Good corrosion resistance helps to extend service life of the items.

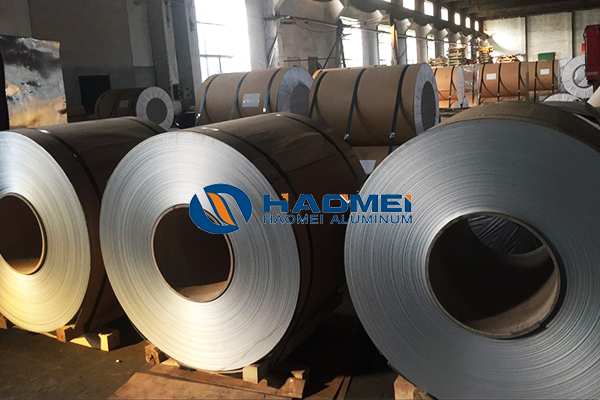

Haomei Aluminum is among leading aluminum coil suppliers in China. After decades of hard work, we have become one of the largest aluminum coil manufacturers in China and an experienced supplier for clients overseas. Welcome to contact us at april@aluminumhm.com for more information!

Nydia

Nydia

Sales Manager

Sales Manager