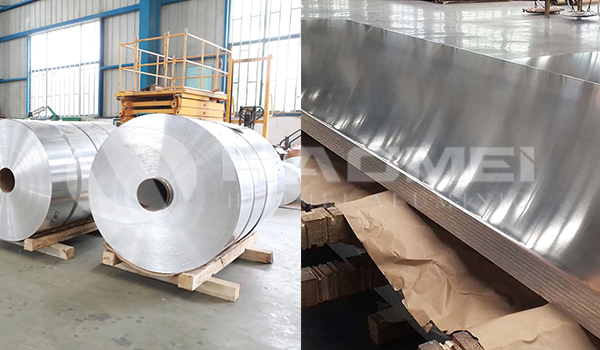

3003 2a12 1050 1060 5083 5052 6061 7075 aluminum coil and sheet and prices of aluminium coil or strip

June 18, 2020

3003 aluminum coil plate is a commonly used aluminum-manganese alloy with excellent anti-rust properties. The strength of this alloy is not high (slightly higher than that of industrial pure aluminum) and can not be strengthened by heat treatment. Therefore, cold working methods are used to improve its mechanical properties. 3003 aluminium plate and strip products are low in price, often used in humid environments such as outer packaging, mechanical parts, refrigerators, and air conditioning vent pipes. A typical product is 3003 aluminum coil for power battery.

2A12 aluminum alloy sheet is a kind of high-strength hard aluminum which can be strengthened by heat treatment and has good spot weldability. 2a12 enjoys a high price, mainly used to make various high-load parts and components (but not stampings and forgings) such as skeleton parts on aircraft. Working parts below 150℃ such as leather, bulkheads, ribs, spars, rivets, etc.

1050 and 1060 aluminum sheet coil belongs to the pure aluminum series. The two share similar chemical and mechanical properties, with high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity, low strength and poor machining ability. With the lowest price of all these alloys, 1050 and 1060 aluminum strips are commonly used in daily necessities, lighting fixtures, reflectors, decorations, chemical industry containers, heat sinks, signs, electronics, lamps, nameplates, electrical appliances, stamping parts etc.

5052 and 5083 aluminium plate sheets are AL-Mg alloy aluminum plates. Magnesium is the main alloying element in 5052 and 5083 alloy products. As the most widely used rust-proof aluminum, the two alloys boast high strength, especially with fatigue resistance. 5052 and 5083 ranks middle in price of the alloys. 5083 aluminum plates are commonly used in ships, ships, vehicle materials, automotive and aircraft plate welded parts, pressure vessels that require strict fire protection, refrigeration devices, TV towers, drilling equipment, transportation equipment, missile components, armor, etc. A typical product of 5052 alloy is 5052 Aluminum Coil for Venetian Blind.

6061 aluminum alloy sheet and coil is an Al-Mg-Si series alloy with medium strength, excellent processing properties, good corrosion resistance, high toughness, no deformation after processing, easy coloring film, and excellent oxidation effect. The price of 6061 is really high, but a little lower than 7075. 6061 aluminum coil sheet is used for various industrial structural parts that require a certain strength, weldability and high corrosion resistance, such as manufacturing trucks, building construction, ships, trams, furniture, mechanical parts, precision processing, and a wide range of industrial materials.

7075 aluminum plate is a cold-treated forged alloy with high strength, general corrosion resistance, good mechanical properties and anode reaction. It is used to manufacture aircraft structures and other high-stress structural parts that require high strength and strong corrosion resistance. 7075 is the most expensive of all these alloys, for its process is more complicated.

Nydia

Nydia

Sales Manager

Sales Manager