3003 2a12 1050 1060 5083 5052 6061 7075 aluminum alloy

September 15, 2020

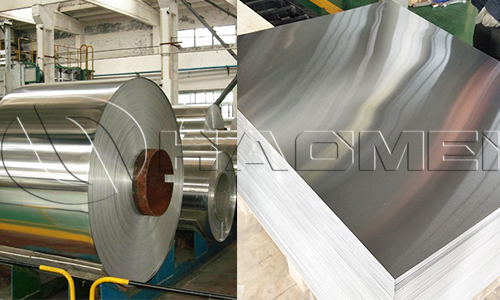

3003 2a12 1050 1060 5083 5052 6061 7075 aluminum coil and sheet aluminium coil or strip covers 1xxx, 3xxx, 5xxx, 6xxx and 7xxx series and their all possible shapes. Here we deal with only the representative alloy of each series.

1050 aluminum coil is the representative of 1xxx series. In addition to the coil type, 1050 can also be made into sheets and strips. It has low density, weak hardness, good corrosion resistance and low price. 1xxx aluminium is so widely used that it finds its applications from cookware to industrial tanks, from printing plates to traffic signs, and from batteries to pipelines.

2a12 usually exists in the sheet type. It belongs to high-strength aluminum, which can be strengthened by heat treatment and has good spot welding ability. The characteristic of the 2xxx series of aluminum plates is their high hardness. Among them, the copper content is the highest, about 3-5%. The 2 series aluminum plates mainly include: 2A06, 2A10, 2A12, 2A16, 2014, 2017, 2024, 2124, 2224, 2524 and other alloy grades, mainly used in aerospace and other fields.

3003 aluminium alloy is usually of coil and sheet type in production. It fully deserves the representative of 3xxx series (Al-Mn alloy), featured by good formability, corrosion resistance and weldability. 3003 aluminum coil is often used to make power battery shells in lightweight automobiles, cookware, food storage devices, tanks and bins on transportation equipment, metal sheet pressure vessels and pipes.

5052 and 5083 are mostly of plate type. The main difference between the two is that 5083 is stronger in hardness and marine corrosion resistance. 5052 aluminum sheet alloy is mainly used in oxidation materials, trolley boxes, fuel tank materials, 3C products, tank materials, silos, mask machines, etc, and 5083 in ship plate, LNG storage tank, gas tank, GIS shell, car body skin, flange material, etc. In addition, 5052 is made into aluminium strips, too.

6061 represents 6xxx aluminium alloys, the main type of which is plate. It mainly contains two elements of magnesium and silicon. 6061 is a cold-treated aluminum forged product, suitable for applications with high requirements for corrosion resistance and oxidation.

7075 is the most popular of 7xxx aluminium alloy. It’s usually of plate type. It mainly contains zinc. It also belongs to the aerospace series. It is an aluminum-magnesium-zinc-copper alloy and a heat-treatable alloy. It is a super hard aluminum alloy with good wear resistance. It is used for the manufacture of high-stress structural parts and molds that require high strength and strong corrosion resistance.

Nydia

Nydia

Sales Manager

Sales Manager