Product Categories

- Aluminum Coil (49)

- Aluminum Strip (28)

- Aluminum Tread Plate (23)

- Aluminum Foil (13)

- Aluminum Slugs (4)

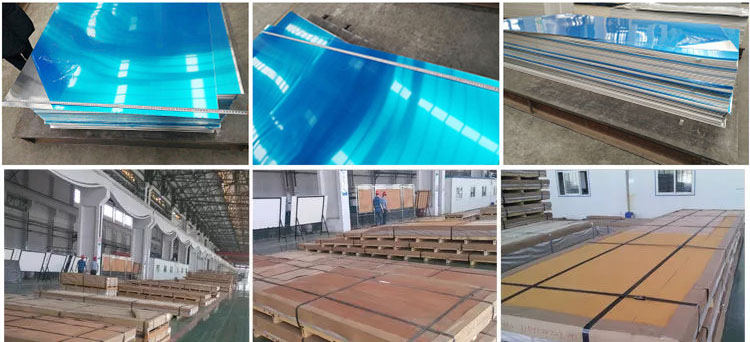

- Aluminum Sheet (46)

- Aluminum Profile (16)

- Aluminum Circle (21)

- Color Coated Aluminium (22)

- CTP Plates (3)

Temper: F, O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H111, H112, H114

Thickness(mm): 0.1-500

Width(mm): 20-2650

Length(mm): 500-16000

enquiryTemper: F, O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H111, H112, H114

Thickness(mm): 0.1-500

Width(mm): 20-2650

Length(mm): 500-16000

| Weight% | Si | Fe | Cu | Mn | Mg | Cr | Zn | B | Ga | V+T | Cr+Mn+Ti+V | Others |

| 1350 | 0.1 | 0.40 | 0.05 | 0.01 | – | 0.01 | 0.05 | 0.05 | 0.03 | 0.02 | – | 0.03 (each) 0.10 (total) |

| 1350A Germany |

0.25 | 0.40 | 0.02 | – | 0.05 | – | 0.05 | – | – | – | 0.03 | 0.03 (each) |

1350 aluminum alloy has the minimum aluminium content of 99.5 %. Alloy 1350 is a non-heat treatable and is the alloy of choice for electrial condutors. It contains a minimum of 99.5% aluminum and are more electrically conductive than other 1000 series aluminum. 1350 aluminum alloy sheet is used in various applications but its main uses are electrical conductors pins, rods, and rivets. This alloy can also be found in various wire form and clips where strength is not as important as economics. NB: 1350 has a tigher chemistry specification and is therefore often used in stead of 1050A. Although other aluminum items have higher aluminum content, most find those alloys as difficult to source and are exponentially more expensive than the 1350 and 1050 aluminum alloys.

Aluminum alloys 1050 and 1350 do have one specific difference in where the chemical composition of 1050 has a slightly higher max on its silicon content than 1350. It is a very small difference and they are both present as maximum values, but the small difference could affect critical applications.

1350 o aluminum coil sheet is a commercially pure, very ductile in extruded condition. It has an excellent resistance to corrosion and excellent electrical conductivity.

Mouldings, lightly stressed and decorative assemblies in architecture and transport, chemical, food and brewing equipment, heat exchangers.

F – As fabricated

There is no special control over thermal conditions and there are no mechanical property limits.

O – Annealed

Applies to products that are annealed to obtain the lowest strength temper.

H111 & H112

Strain hardened tempers via the extrusion process to develop minimum property requirements.