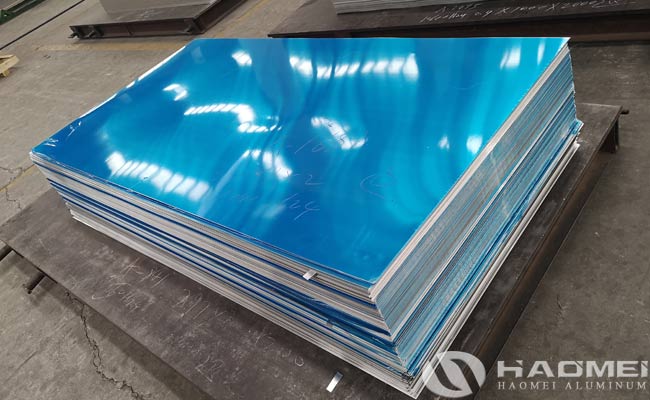

1100 Aluminum Sheet

March 31, 2023

1100 aluminum sheet is an ordinary pure aluminum sheet with aluminum content 99%, it is common used with 1060 aluminum sheet 1XXX series aluminum grades. The production process of 1100 grade aluminum sheet is electrolytic aluminum liquid – batching – refining in the furnace – resting – adding grain refining agent – online degassing and filtering – casting and rolling – cold rolling – annealing – cross cutting – packaging – storage.

The main properties of 1100 aluminum sheet is depend on electrical and mechanical properties. Al1100 aluminum sheet has the following characteristics:

1, Good hot working and cold working properties.

2, Excellent corrosion resistance and weldability.

3, Anodic oxidation improves its corrosion resistance in one step.

4, Anodic oxidation provides an aesthetically pleasing surface.

5, Can be gas welding, argon arc welding, spot welding.

6, Mature process and stable quality.

7, The material has uniform organization and low density.

Al1100 aluminum sheet chemical composition:Al99 Si+Fe0.95 Cu0.05-0.2 Zn0.1 Mn0.05

The mechanical properties of aluminum alloy Al1100 aluminum sheet at room temperature are as follows:

Tensile strength 90-165MPa.

Yield strength 35-150 MPa.

Shear strength 60-90 MPa.

Fatigue strength 35-60 MPa

Elongation 6-35%.

Hardness 23-44HB

The physical properties of Al1100 aluminum sheet at room temperature are as follows:

Modulus of elasticity: 69GPa.

Density: 2.8g/cm3.

1100 aluminum sheet is widely used in various fields from cookware to industrial equipment. Its main uses are as follows:

1, Generally used in utensils, heat sinks, bottle caps, printing plates, building materials, heat exchanger components.

2, Also can be used as deep-stamping products.

3, For aluminum rows and busbars of electrical components, sheet metal parts, nameplates and decorative plates.

4, For processing parts with low strength but requiring good formability and high corrosion resistance.

5, Welded parts, heat exchangers, clock faces and plates, nameplates, reflective appliances, etc.

Nydia

Nydia

Sales Manager

Sales Manager