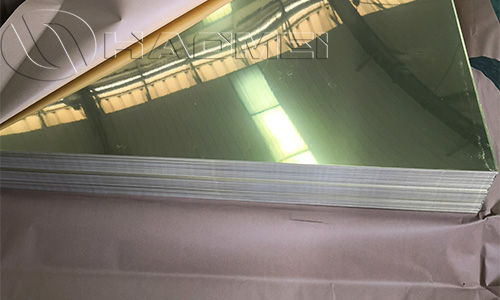

1060 1085 heat reflective aluminum sheets

July 15, 2021

1060 and 1085 heat reflective aluminum sheets represent two levels of solar reflective aluminium sheet in processing methods, reflectivity, mechanical properties and prices.

The 1060 heat reflective aluminium sheet is fabricated from 1060 aluminium ingot by continuous rolling. If the rolling machine is not a mirror roller, an extra polishing step must be added. However, polished aluminium sheets perform poorer in practical uses, thus Haomei has discarded such a process. All its 1060 reflective alu sheets are made by rolling, hot water washing and filming directly. In this way, the reflectivity reaches 86% and gets more durable than polished sheets. 1085 aluminium sheet is usually imported from American or European countries. It’s the best candidate for an anodized reflective aluminum sheet, the reflectivity of which reaches 95% and 96%. 1060 sheet can also be anodized, but the effect does not worth the cost of the process. 1085 sheet should be mirror finished first, and then anodized. The price of the finished sheets is very higher, times of that of 1060 heat reflective aluminum sheets.

The regular thicknesses of Haomei 1060 and 1085 heat reflective aluminum sheets include 0.28mm, 0.3mm, 0.4mm and 0.5mm, 0.8mm and 1.0mm. If you need thicker sheets, those of 3mm is available, too. The width is up to 1250mm. As a matter of fact, 1060 sheets are also applied to grill lights, and the sheet can be embossed if necessary. The price is more cost efficient than 1085 sheets.

Nydia

Nydia

Sales Manager

Sales Manager