Polyester Coated Aluminum

August 21, 2023

Polyester coated aluminum are paint coated sheet metal made from PE polyester coating on metal sheets and then baked at high temperatures. Due to the good adhesion, easy processing and shaping, wide range of color and gloss options, and low price, PE polyester coated aluminum sheet are the most widely used colored coating aluminum products. They are mainly used in industrial and low-pollution environments such as ordinary industrial plants and logistics warehouses.

When used for factory walls, roofs, warehouses, portable rooms, and interior decoration, under normal use conditions, correct processing and installation conditions, The polyester coated aluminum sheet can be maintenance-free for 8-10 years, with low usage costs and high cost performance.

The coating thickness of our pe coated aluminum coil is generally 15-18 micrometers for single coating, 25-28 micrometers for double coating, and 25-28 micrometers for fluorocarbon coating. The back coating is commonly used in white or gray colors. The coating thickness is 5-8 micrometers.

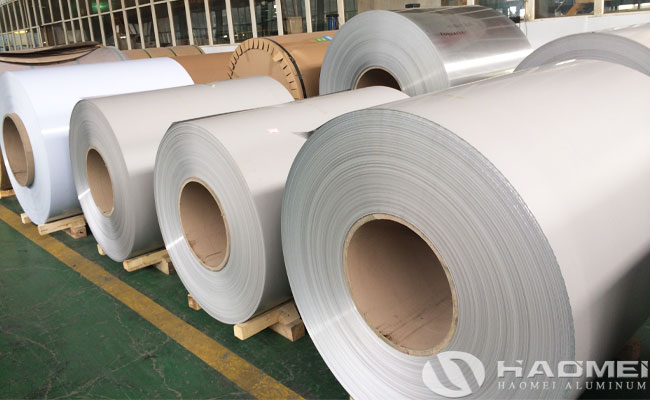

Polyester coated aluminum coil

Application: Very wide, such as aluminum-plastic panels, aluminum roofing sheet etc.

Grade: 1100/3003/3005/8011, etc.

Condition: H14-H48, etc.

Thickness: 0.04mm-0.5mm

Width: <1590mm

Color: Gray white base, blue silver, etc.

Single coil weight: Generally around 2.5 tons

Inner core: Paper tube

Diameter: 150mm, 405mm, 505mm

Product features

PE polyester coated aluminum have good adhesion, easy processing and shaping, a wide range of color and gloss options, and low price. However, they have average corrosion resistance, resistance to UV radiation, and anti-powdering performance, so they are not suitable for industries and environments with severe pollution.

Nydia

Nydia

Sales Manager

Sales Manager