Aluminium 5083 Suppliers

November 14, 2022

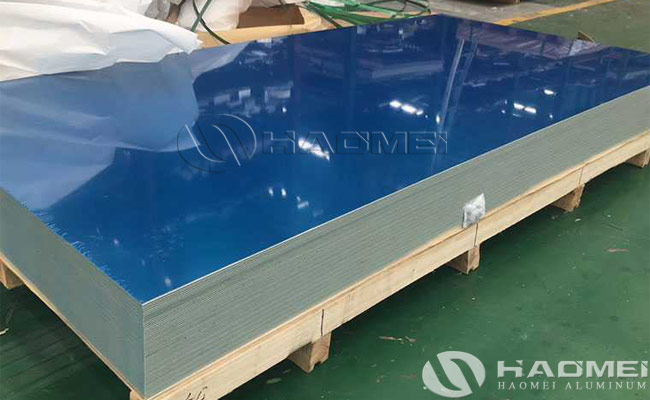

Aluminium 5083 suppliers offer prime 5083 aluminum product with O, H111, H116, H321 used for shipbuilding, tooling plate and trailer tanker body. Aluminium 5083 is the highest strength material among non-heat-treated aluminum alloys (1000 series, 3000 series, 4000 series, 5000 series). It has good corrosion resistance and weldability. Because it is a material with excellent seawater resistance and low temperature characteristics, it is not only used for pressure In addition to containers and containers for low temperature, it is also used as a material for welding structures in ships, vehicles, and chemical plants. The Mg content is also relatively high in the 5000 series. In addition, aluminium 5083 is a material used when it is limited to the side plates, annular plates and knuckle plates of LNG storage tanks.

At present, 5083 aluminum alloy plate is more and more widely used in the shipbuilding industry, from small self-propelled sampans, motor boats, to large ships of 10,000 tons. From civilian to military, from high-speed hovercraft to deep-water submarines, from fishing boats to marine mining vessels, high-performance 5083 aluminum plate alloy materials are used as hulls, superstructures, various facilities, pipelines and even appliances. Aluminium 5083 suppliers also provide certification for marine grade aluminium 5083 for quality assurance when applied to marine industry, the certification including ABS, CCS, DNV, LR, KR, BV and so on.

The construction and working environment of ships require that materials should have good corrosion resistance, weldability, plasticity and sufficient tensile strength, yield strength, elongation, impact resistance and other properties. To meet these properties, aluminium 5083 suppliers find that the aluminum alloys with the most applications and the best effects on ships include industrial pure aluminum, Al-Mg series and AI-Mg-Si series alloys. In recent years, Al-ZnMg alloys have also attracted increasing interest.

Nydia

Nydia

Sales Manager

Sales Manager