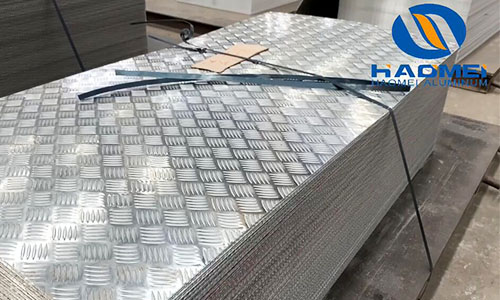

Aluminium chequered plate 5754 for flooring

April 19, 2021

An aluminium chequered plate 5754 for flooring has medium strength, good corrosion resistance, excellent welding property and good forming property. It’s among the most popular alloys of 5000 series of aluminium. It contains 2.6% to 3.6% magnesium, less than that of 5083, which is 4.0% to 4.9%. Therefore, its hardness is weaker than 5083. However, the strong anti-rust ability and outstanding forming property makes it equally popular with 5083. In fact, 5083 and 5754 aluminium chequered plates are two representative checker plates of the 5000 series.

The 5754 aluminium chequered plate is used for flooring because of its excellent anti-skid property and wear resistance. Ordinary patterns for the plate include five bar and 1 bar, with 5 bar the most frequently applied, for its anti-slip performance proves to be better. As a typical Al-Mg alloy, 5754 aluminum plate has excellent integrated mechanical properties. It has a tensile strength of 165~265Mpa, ranking high in Al-Mg alloys. This endows it with prominent wear resistance, which extends the service life of 5754 chequered plates. Even though the patterns get worn out over the years, you do not have to discard the plate and purchase a new piece. A kind of aluminium checker plate tape is available. Stuck to the surface of old flooring aluminium plates, the tape acts as a new anti-skid layer of the plates.

Aluminium chequered plates 5754 are applied to the flooring of platforms, vehicles, ships, cold storage houses, shopping malls, elevators, steps, workshops, railway stations, train stations and so on. Most of these application conditions can be filled by 1000 series of aluminium chequered plates, mostly 1060-h24, but in some cases where load bearing function is needed, 5754 is more suitable. 5754 plates also boats better corrosion resistance. Needless to say, its price is higher, too. Therefore, you do not have to choose 5754 in anti-skid flooring unless it’s necessary.

Nydia

Nydia

Sales Manager

Sales Manager