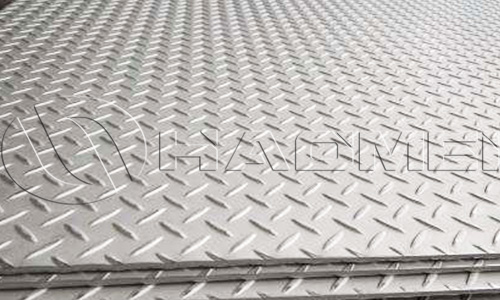

Aluminium checker plate for ramp

April 6, 2021

An aluminium checker plate for ramp is a little different from ordinary anti-skid aluminum plates. In most cases aluminium tread plates stretch on stairs or by metro station entrances and elevator doors to prevent people from slipping, especially in rainy days or in places with lots of water. A ramp aluminium checker plate, however, functions not only to resist skid, but also to bear the weight landing on it, for most of its part is suspended, without any support. Therefore, such a plate must be strong enough in hardness. This excludes weak alloys like 1060 and 3003. Instead 5052, 5754, 6061, 6063 and 6082 are more suitable.

5000 and 6000 alloys are excellent in both hardness and corrosion resistance. Theoretically 6000 ones are harder. They contain silicon and magnesium, belonging to the heat treatable strengthened aluminum alloy. They have advantages of high corrosion resistance, zero stress corrosion cracking tendency, good welding performance, unchanged corrosion performance of the welding zone, and good processing performance. The most widely used 6-series alloys are 6061 and 6063 alloys, which have the best comprehensive properties and can be used as building materials. Therefore, the hardness of a 6xxx aluminium checker plate is qualified for ramps.

An aluminium checker plate for ramp is used for ramps for wheelchairs, barrows, e-bikes etc. Take wheelchair ramps for example. They are slopes of no more than 1/12, replacing steps at the entrance of a public building. The clearance width of the building corridor ramp is generally more than 1.3 meters, and the public elevator ramp is generally more than 0.8 meters. Therefore, a 1.5m wide aluminum checker plate is enough for wheelchair ramps. The thickness should be at least 1mm. Checker plates for other ramps can be customized based on the specific requirements of load, width and angle between the ramp and the ground level.

Nydia

Nydia

Sales Manager

Sales Manager