Product Categories

- Aluminum Coil (49)

- Aluminum Strip (28)

- Aluminum Tread Plate (23)

- Aluminum Foil (13)

- Aluminum Slugs (4)

- Aluminum Sheet (46)

- Aluminum Profile (16)

- Aluminum Circle (21)

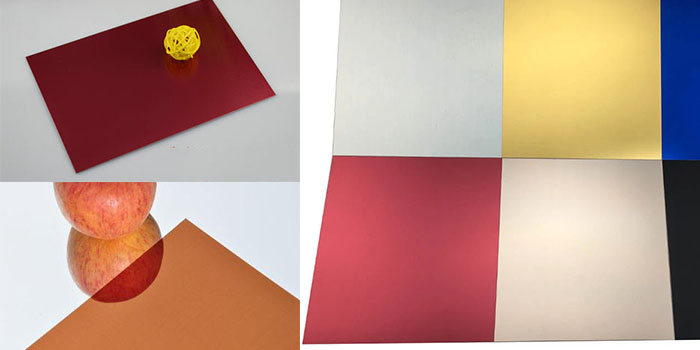

- Color Coated Aluminium (22)

- CTP Plates (3)

Alloy: 1050 1060 1100 3003, 3105, 5052, 5005, 5754 5083 5182, 6061 6063 6082, 7075

Temper: HO, H111,H12, H14, H24,H 32, H112, T4, T6, T5,T651

Thickness: 0.2mm-8mm

Width: 100mm to 2650mm

Surface: bronze anodized, brushed, copper mirror finished

Bronze anodized aluminum sheet is a copper-color sheet metal product consisting of aluminum sheeting exposed to an electrolytic passivation process that imparts a tough, hard-wearing protective finish on its surface. The protective layer formed by the anodizing process is actually little more than an enhancement of the natural oxide layer that exists naturally on the surface of the aluminum.

Alloy: 1050 1060 1100 3003, 3105, 5052, 5005, 5754 5083 5182, 6061 6063 6082, 7075

Temper: HO, H111,H12, H14, H24,H 32, H112, T4, T6, T5,T651

Thickness: 0.2mm-8mm

Width: 100mm to 2650mm

Length: up to 16000mm

Surface: bronze anodized, brushed, copper mirror finished

Copper anodized aluminum sheet is widely used in machinery parts, aircraft and automobile parts, precision instruments and radio equipment, building decoration, machine housing, lighting, consumer electronics, crafts, household appliances, interior decoration, signage, furniture, automotive decoration and other industries.

| Chemical Composition – copper colored anodized aluminum sheet | ||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Al |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | – | – | 0.05 | 0.03 | Remains |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | – | – | – | – | – | Remains |

| 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | – | – | – | – | Remains |

| 1100 | 0.95 | 0.95 | 0.05-0.2 | 0.05 | – | – | 0.1 | – | – | Remains |

| 1200 | 1 | 1 | 0.05 | 0.05 | – | – | – | 0.1 | 0.05 | Remains |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | – | – | – | 0.1 | – | Remains |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.5-1.1 | 0.1 | – | 0.25 | – | Remains |

| 5042 | 0.2 | 0.35 | 0.15 | 0.2–.5 | 3.0-4.0 | 0.1 | – | 0.25 | 0.1 | Remains |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | – | 0.1 | – | Remains |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | – | 0.25 | – | Remains |

| 5754 | 0.4 | 0.4 | 0.1 | 0.5 | 2.6-3.6 | 0.3 | – | 0.2 | – | Remains |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | – | 0.25 | – | Remains |

| 6063 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45 | 0.1 | – | 0.1 | – | Remains |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.4-1.0 | 0.6-1.2 | 0.25 | – | 0.2 | – | Remains |

| 7050 | 0.12 | 0.15 | 2.0-2.6 | 0.1 | 1.9-2.6 | 0.04 | – | 5.7-6.7 | 0.06 | Remains |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | – | 5.1-6.1 | 0.2 | Remain |