Product Categories

- Aluminum Coil (49)

- Aluminum Strip (28)

- Aluminum Tread Plate (23)

- Aluminum Foil (13)

- Aluminum Slugs (4)

- Aluminum Sheet (46)

- Aluminum Profile (16)

- Aluminum Circle (21)

- Color Coated Aluminium (22)

- CTP Plates (3)

Thickness: 0.012mm-0.2mm

Maximum width: 1650mm

Alloy: 1235, 1145, 3A21, 8006, 8011, etc

Status: general supply status h18, H24, O, H16, H24, H26, H22, H14, H12

enquiryHeavy duty aluminum foil can be further divided into common heavy duty tin foil, extra heavy duty aluminum foil, super heavy duty aluminum, great value heavy duty aluminum foil and extra wide heavy duty aluminum foil. The former four relates to thickness of the foil, and the last to width of the foil. Heavy duty foil sheets are cheap, durable, non-toxic and oil resistant, used widely as an industrial aluminium foil in packaging industry. The use of aluminum foil in soft packaging can extend the shelf life of packaging products, occupy less storage space, and generate less waste than many other packaging materials. In addition, heavy duty cater foil is another popular application.

Haomei has heavy duty, extra heavy duty, super heavy duty and great value heavy duty aluminium foil sheets of 8011, 8021, 1235, 1070, 1100, 3003, 3004, 8079, 5052 etc. They fall on the following categories by application scopes.

General Heavy Duty Aluminum Foil

Thickness: 0.012mm-0.2mm

Maximum width: 1650mm

Alloy: 1235, 1145, 3A21, 8006, 8011, etc

Status: general supply status h18, H24, O

Application: thermal insulation, moisture-proof and other construction fields

Various packaging materials, containers, composite materials, power electronics industry

such as tapes, packaging materials, utensils, etc

Our Order Treatment Procedure

According to the test report, our heavy duty aluminium foil sheets complies with the FDA regulations on direct contact with food packaging materials. The total content of lead, cadmium, mercury and hexavalent chromium complies with the provisions of Council Directive 94 / 62 / EC. After receiving the customer’s order, we will review it and transform it into the technical requirements required for production (including alloy, state, thickness, width, coil inner diameter, coil outer diameter and mechanical characteristics), and then process it.

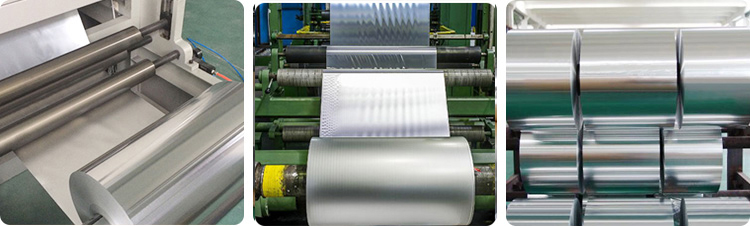

We use precision machines, which have more stringent production error control capabilities, so that we can produce high-quality heavy duty aluminium foil and reduce the production time loss caused by equipment defects. We mainly buy equipment from European manufacturers and use European and Japanese technology to operate equipment.

We closely monitor production procedures and conduct performance and reliability tests to ensure that products meet customer expectations and achieve low defect rates. Our process data analysis system monitors product quality by collecting production data in real time.

Our on-site testing combines a variety of strict testing techniques, and the test results of each production post become an important part of the employee evaluation standard. In addition, we regularly communicate with customers to obtain feedback on quality standards of our industrial heavy duty aluminum foil rolls.

Both regular and heavy duty aluminum foil are made of the same material: aluminium. The difference lies in their thickness. Thin aluminium foil rolls are only 0.006mm thick, yet thick ones can be up to 0.2mm thick. As the name implies, heavy duty aluminium foil simply refers to a kind of aluminum foil that is thicker, sturdier and thus heavier than regular aluminum foil. Correspondingly thicker aluminium foil has a much heavier weight, which results in directly a higher price per area unit.