Aluminum coil sheet a1050 h24

March 18, 2020

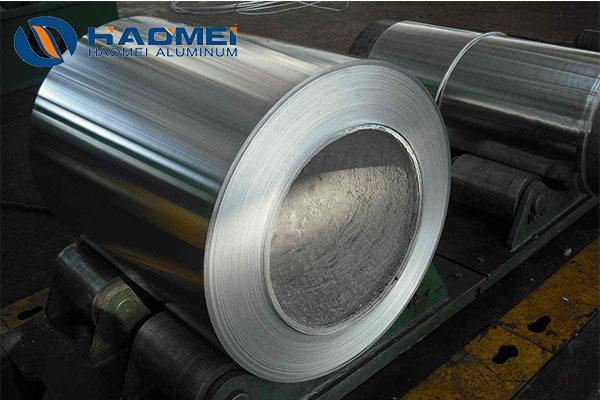

Aluminum coil sheet a1050 h24 is of thickness between 0.2mm and 8mm, suitable for complicated punching, bending and stretching. Medium hardness and good elongation make it an excellent material for ctp and ps plates, plastic aluminum composite panels, lighting panels, battery anti-explosion material, sign boards, insulation coil sheets and so on. H24 refers to the processing hardening after incomplete annealing, which makes the sheet coil into medium hardness. The process includes intermediate annealing and cold rolling. 1050 h24 aluminum coil as hard as 1050h14 coil, but its elongation is better. A1050-h24 aluminum coil sheet is often used in lighting appliances, reflective boards, decorations, chemical industry containers, heat sinks, labels, electronics, lamps, nameplates, electrical appliances, stamping parts and other products. In some cases where both corrosion resistance and formability are required, but strength requirements are not high, chemical equipment is its typical use.

The width of h24 1050 aluminum coil sheet ranges from 100mm to 1650mm. Though it’s called coil sheet, the standards are based on those for coils in production, for coils can be further made into sheets if you need. The coil has the characteristics of high plasticity, corrosion resistance, good conductivity and thermal conductivity. As a member of pure industrial aluminum, it has a low strength that can not be strengthened by heat treatment. Its biggest advantage over other series lies in simple process and low price.

Nydia

Nydia

Sales Manager

Sales Manager