Classification of aluminium circles for utensils

March 10, 2020

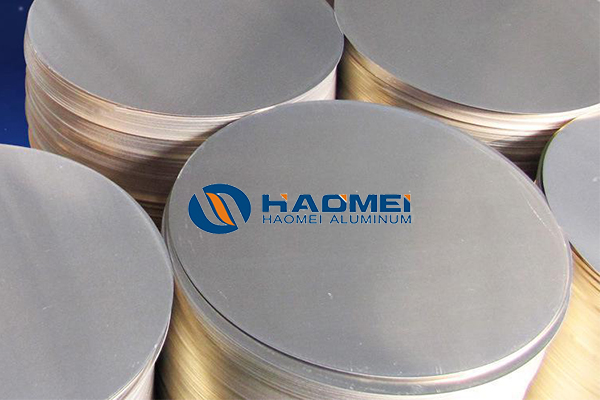

The classification of aluminium circles for utensils falls on four categories: alloy, rolling type, surface treatment methods and further process methods.

By alloys there are 1050, 1060, 1070, 1100, 3003, 3004, 3005 and 5052. These are regular ones, sometimes special alloys are adopted. Basic differences of these alloys lie in hardness, tensile strength and corrosion resistance. 1xxx series, containing the biggest share of aluminium, are the weakest in strength. 3xxx and 5xxx circles prove to be harder, and they overshadows 1xxx circle sheets in corrosion resistance as well, for both series are known as corrosion resistant alloys. Although they are harder, their tensile strength is excellent owing to the adding of alloying metals.

By rolling types we have cold rolled and hot rolled aluminium circles for utensils. Cold rolling plates are processed by a casting and binding machine into a cast coil (8mm thickness) and processed by a cold rolling machine, while hot rolling is by heating an aluminum plate ingot (400-500mm thickness) and rolling at a high temperature by a hot rolling machine. The surface quality of hot-rolled aluminum sheets is good, the mechanical properties and ductility strong, and the oxidation effect outstanding. These plates are later processed into aluminum circles that obtain similar properties. Cold rolled circles show a poorer elongation than hot rolled discs, and their surface are brighter. Generally speaking, hot rolled aluminum circles are better materials for utensils, either as deep drawing or as spinning circle aluminum plates.

By surface treatment and further process methods we refer to mill finish, coated, deep drawing and spinning. Mill finish circles take up the largest share in the market, since they are mostly made into pots, strainers and lids that require no special surface treatment. Pre-painted aluminum circle discs are used for making higher-end cookware like high pressure cookers. There are two further process methods for aluminum circles: deep drawing and spinning. The former produces cylindric items while the latter tapered ones.

If you search further, there might be other method for classification of aluminium circles for utensils, thus it’s open to discussion.

Nydia

Nydia

Sales Manager

Sales Manager