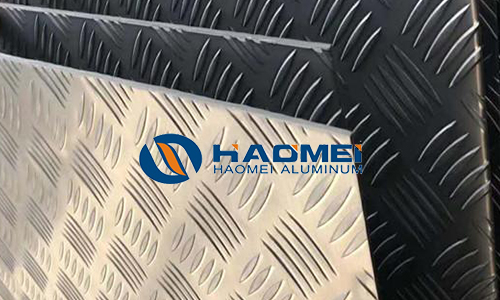

Anti skid anodized aluminium sheet

February 24, 2020

An anti skid anodized aluminium sheet refers to an aluminum checker plate that has been anodized. In comparison to regular checker plates, anodized sheets, with a hard anodizing film, boast a more excellent corrosion resistance and a longer service life. Regular alloys for the sheets include 1050, 1060, 1070, 1100, 3003, 3004, 3104, 5052, 5083, 6061 etc.. The most frequently applied ones are 1xxx, 3xxx and 5xxx series. 1xxx, mostly 1060, are very soft and usually used for flooring of trucks, elevators and refrigeration rooms. 3xxx and 5xxx plates, stronger and more corrosion resistant, are made into wall cladding materials and flooring panels withstanding heavier friction forces.

The patterns of anti skid aluminum sheets incorporate five-bar, one-bar, three-bar, two-bar and four-bar, among which the former two are the most frequently adopted. In addition to patterns, thickness is part of the specification of a plate, too. If an anti skid anodized aluminium sheet has to carry weight during its application, it must reach a certain thickness. A 2mm aluminium checker plate, for instance, can never bear the weight of an adult whatever alloy it is of. Such a sheet should be at least around 5mm thick. It can be used as a suspended panel of ships or buildings.

Sometimes anti skid anodized sheets are colored, known as patterned colored anodized aluminum sheet products, but they are usually used for making items like tool boxes rather than for anti-slip purposes. Most plates are just anodized to extend their service life.

Nydia

Nydia

Sales Manager

Sales Manager