Do China suppliers have super anodized aluminum sheet

January 21, 2020

An anodized aluminum sheet falls on the category of high-tech semi-processing aluminum products, and the word “high-tech” is usually associated with developed countries in America and Europe. However, such an idea is mistaken in the field of anodizing. China suppliers are capable enough to supply anodized aluminium plates of super quality. There are even excellent anodized aluminum sheet metal suppliers like Haomei.

Some purchasers, including those in China, might frown upon this statement. Why, then, they might ask, is it so difficult to obtain high-end anodising sheets in China? When an aluminum alloy sheet is anodized, a thin layer of aluminum oxide is formed on the surface. The thickness of the oxide is 5-30 microns, and the hard anodized film can reach 25-150 microns. Under normal circumstances, the thickness of the oxide film on the anodized surface of domestic aluminum is 7um-15um, that is, 0.07mm-0.15mm. Thickness of those for non-special uses rarely exceeds 12um, because thicker oxide film means higher cost and price eventually. It is not that China cannot make thicker and better anodized aluminum sheet pieces, but that our current consumption level and demand cannot afford this price. The oxide film is a very uniform, delicate and precise aluminum oxide protective layer. The use effect can be fully achieved as long as it is more than 7um in use in China.

Anodizing aluminium plates from China suppliers have the following features.

(1) Good processing ability: the anodized aluminum plate is highly decorative, moderate in hardness, and can be easily bent and formed for continuous high-speed stamping, which is convenient for direct processing it into products without further surface treatment, and greatly shortens the production cycle and reduce product production costs.

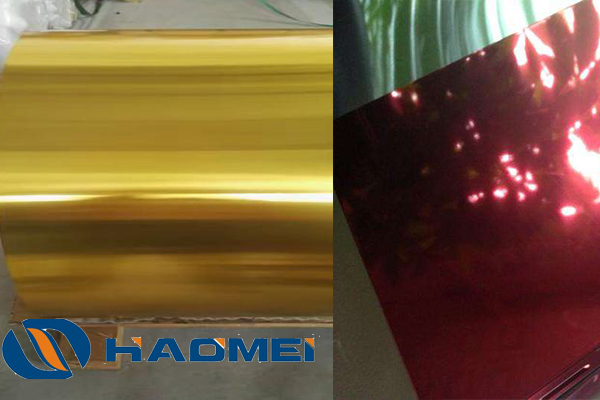

(2) Good weather resistance: Anodized aluminum plate with standard thickness oxide film (3μm) will not change color for a long time in the room. It will not corrode, oxidize or rust. An anodized aluminum plate, like a red anodized aluminum sheet with thick oxide film (10μm), can be used outdoors without changing colors under long-term exposure to sunlight.

(3) Strong metal feeling: An anodized aluminium plate has high surface hardness, good scratch resistance, paint-free surface and modern metal feeling, which improve its product grade and added value. If the sheet is anodized, it’s more popular, for a reflective aluminum mirror sheet has an extra advantage in decoration.

(4) High fire resistance: As pure metal products, the sheets have no paint or any chemical substances on the surface, no combustion at 600 ° C, no toxic gas, and meet the requirements of fire protection and environmental protection

(5) Strong anti-fouling property: No fingerprints or stain marks will be left on the surface. Even though there are stains, they are easy to clean, and no corrosion spots would be left on the surface.

Haomei anodized aluminium sheet products cover a wide range of application, made into metal aluminum ceiling, curtain wall aluminum plates, aluminum plastic panels, fireproof panels, honeycomb aluminum plates, aluminum veneer, electrical panels, cabinet panels, furniture panels and so on.

Nydia

Nydia

Sales Manager

Sales Manager