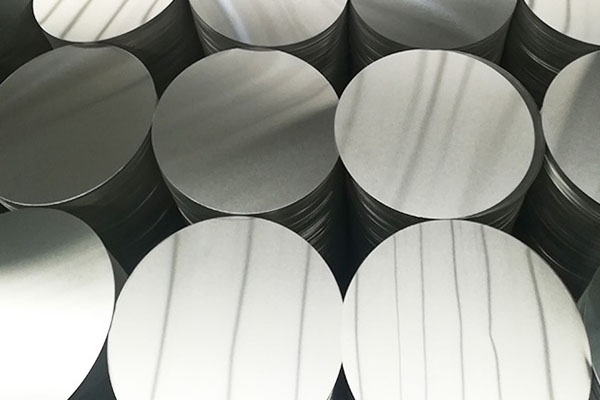

Properties of aluminum circle for cookware

November 26, 2019

An aluminum circle for cookware can be made of many alloys, such as 1050, 1060, 1070, 1100, 3003, 3005, 5052 and so on. Its properties are as below.

First, good corrosion resistance. An aluminum circle, whatever alloy it is of, contains a high content of aluminium that “rusts” easily. Aluminium reacts to oxygen far more faster than iron or copper, but in a quite different result. Iron oxide proves to be a dark brown powder that are so porous that oxygen gets through it to oxidize the inner layer of iron and have a new group of iron oxide powder coming into being. Eventually the whole iron piece will get rusty and disappear. Aluminum oxide, on the other hand, appears as a dense layer of solid item attached firmly to the surface of an aluminum circle for cookware. This layer prevents oxide getting in contact with the inner layer of aluminium. That’s why aluminium cookware, if not anodized or coated, gets a white layer on the surface quickly. Please note that this white layer should not be removed, or else your aluminium pot will get thinner and thinner.

Second, fast heat conductivity. Aluminum circle discs have a heat conductivity of 211.9, second only to silver and copper. Then why many people would rather choose aluminium cookware than copper ones? Because aluminum circles are much cheaper and harder.

Third, wide in hardness range. 1050, 1060, 1070 and 1100 aluminum circle sheets are not so hard as 3003 aluminum circle pieces which are less stronger than 5052 circle. This makes cookware manufacturers have great freedom in choosing raw materials. If they aim to make “disposable” pots which last only months, they adopt 1000 series of aluminum circles, but if they are manufacturing high pressure cookers, they will purchase 5052 aluminum circle featured by a stronger hardness and a longer service life.

Corrosion resistant, fast in heat conductivity and wide in hardness range, the aluminum circle for cookware is winning increasing popularity.

Nydia

Nydia

Sales Manager

Sales Manager