What is pvc color coated aluminum trim coil

July 12, 2019

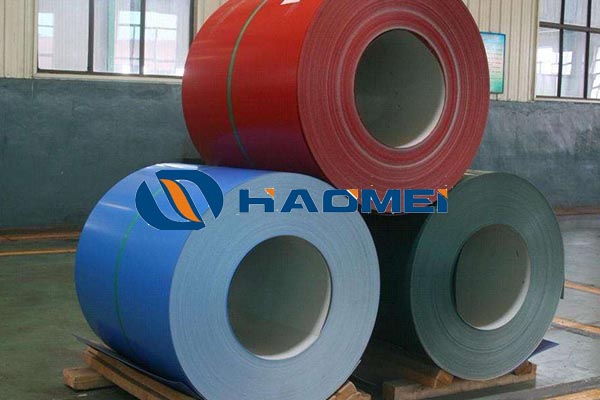

The PVC aluminum trim coil refers to a color coated aluminum coil whose surface or surfaces are coated with pvc paint. PVC paint is the abbreviation of English Polyvinyl Chloride, which is also known as polyvinyl chloride. Using amorphous materials as raw materials, it has excellent properties in oxidation resistance, strong acid resistance and resistance to reduction. Polyvinyl chloride also has high strength and excellent stability, and is non-flammable and resistant to corrosion caused by climate change. It is a very good material, and because of its high safety, it can be seen everywhere in life.

Why is pcv used in color coated aluminum coil? As a global plastic product with a huge output, PVC is divided into two types of soft and hard PVC, which provide different choices for different occasions. Soft PVC is commonly used as a surface material for flooring and ceilings, while hard PVC materials are used more in corrugated sheets, door and window structures, and various chemical industrial manufacturing, all of which can be made of pvc coated aluminum trim coil. And PVC materials are also changeable. By adding different additives, the physical properties of PVC can be changed and its mechanical properties can be adapted to different applications. For example, the soft and hard PVC mentioned above can even be made into a transparent material for special needs.

How is PVC aluminum trim coil in comparison with PDVF color coated aluminum coil?

PVC molding shrinkage rate is 0.6-1.5%. Aluminium trim coils with such a paint has good mechanical properties, excellent electrical properties, self-extinguishing, strong acid and alkali resistance, good chemical stability, low price, and is a very widely used plastics. However, low temperature withstanding ability (only 80 degree centigrade) greatly hinders its development.

While the appearance of PVDF is translucent or white powder or granules. The molecular chains are closely arranged and have strong hydrogen bonds. The oxygen index is 46%, non-combustible, crystallinity is 65%~78%, and the density is 1.17~1.79g/ Cm3, melting point is 172 ° C, heat distortion temperature 112 ~ 145 ° C, long-term use temperature is -40 ~ 150 ° C.

Therefore, pvc coated aluminum trim coil cannot compete pvdf color coated aluminium coil in either quality or service, but the latter is almost ten times more expensive! As the saying goes, you cannot get both quality and price.

Nydia

Nydia

Sales Manager

Sales Manager