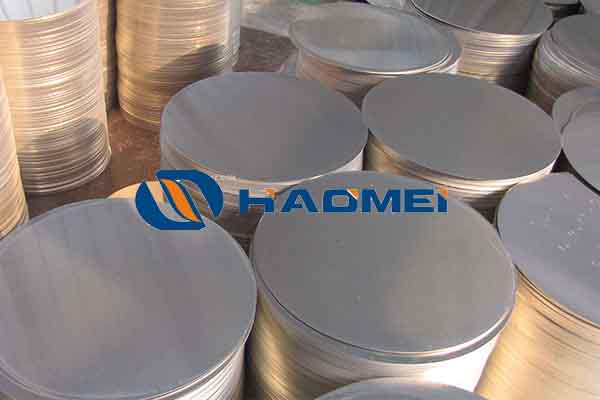

Why is the aluminum round disc used for heater shells

June 19, 2019

The aluminum round disc covers a wide range of application, among which is shell for heaters. It’s used for heater shells based on its advantages of a perfect raw material, including good heat withstanding performance, easy processing, satisfying corrosion resistance, good insulation and long service life.

The aluminum round disc withstands high temperature without getting deformed, especially when it has been coated. Of medium hardness among metals, the disc is adaptable to various processing requirements in cutting, bending, drilling and welding. This makes it possible for water heater manufacturers to process it at will to meet varied design styles. Aluminum circle discs have a natural advantage over other metals that it shows excellent corrosion resistance. It’s not that they not react to other chemical elements, but that they react to the oxygen so quickly that a layer of oxide aluminium comes into being on their surface within hours. The oxide functions as a protective layer against most corrosive materials. Coated discs are even more corrosion resistant, and they have excellent insulation performance as well. Last but not least, aluminium discs are light and strong enough to hold the weight of water.

In a word, the aluminum round disc is used for heater shells because it’s corrosion resistant, light, hard and easily processed.

Nydia

Nydia

Sales Manager

Sales Manager