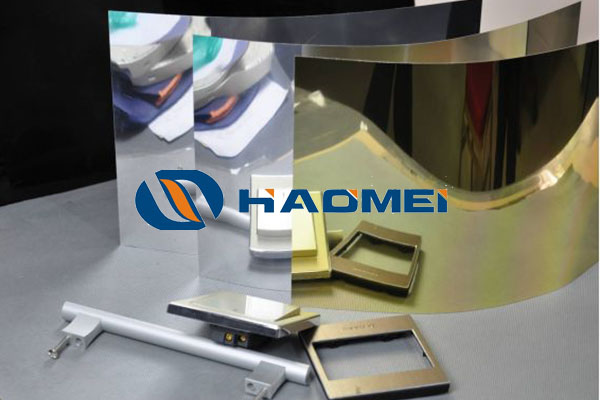

Aluminum mirror reflect sheet for reflective panels

May 30, 2019

One the the usages of the aluminum mirror reflect sheet is as a raw material for reflective panels of solar heat collecting systems. What are its advantages, then?

The basic requirement of reflective panels are high reflectivity, which paves way to efficient heat collecting from the sunshine. As its name hints, the aluminum mirror reflect sheet is a kind of mirror in a way. Even the most inferior ones can reflect around 80% light reaching its surface, functioning much better than traditional copper mirrors. The reflectivity of better aluminum mirror reflect sheets reaches 86%, and the best ones 95% and above, thus there’s no problem for the sheet as a perfect reflective material in reflectivity. In addition, aluminium sheets are much lighter than other metal sheets, for the aluminium element has a smaller density, only about one third of steel, not to mention copper. A light reflective panel helps to reduce weight of a solar system greatly. Last but not least, the aluminum mirror sheet has a long service life. There are two kinds of alu mirror sheets: polished ones and anodized ones. The former lasts shorter, but those used in solar systems are usually mirror anodized aluminum sheets that has an anodizing film on the surface that acts as a protective layer and prolongs the sheets’ service life substantially.

Based on the information above, the aluminum mirror reflect sheet is used for reflective panels of solar systems because of its high reflectivity, light weight and long service life.

Nydia

Nydia

Sales Manager

Sales Manager