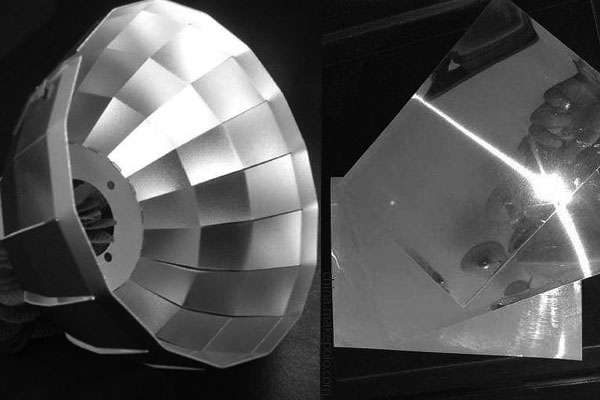

Aluminum mirror reflector sheet for lighting

May 22, 2019

Why is the aluminum mirror reflector sheet so widely applied? You will not wonder any more after learning about its pros.

An aluminum mirror reflector sheet has a good heat dissipation. Going through the thermal electric separation technology, the sheet obtains a much higher thermal conductivity (137W), which greatly improves heat dissipation of the chip, while the thermal conductivity of the aluminum substrate with ordinary insulating layer is only 1W, 1.5W or 2W. A better chip benefits an electronic product a lot. Another pro of the aluminum mirror sheet is its high light efficiency. The reflectivity of our common aluminum sheets is about 80%, the reflectivity of the aluminum plate of the cup hole is 85%, the silver plated aluminum substrate is 95%, and the mirror silver aluminum substrate 98%. It can be seen that the mirror silver aluminum substrate can make the light of the chip better excited and brighter in the use of lamps. Finally, the aluminum reflector sheet is easy to operate. The mirror silver aluminum substrate structure is similar to the integrated bracket used in our market. The circuit is connected with gold wire by gold wire. The series and parallel connection and packaging can be made at will. It is not like an ordinary chip placed on one pad, and the mirror silver aluminum substrate can seal several W-number lamps, solving the problem of excessive inventory models.

In a word, the aluminum mirror reflector sheet is used for lighting because of its good heat dissipation, high light efficiency and easy operation.

Nydia

Nydia

Sales Manager

Sales Manager