Advantages of Mirror Finish Anodized Aluminum Sheet over Glass

March 14, 2019

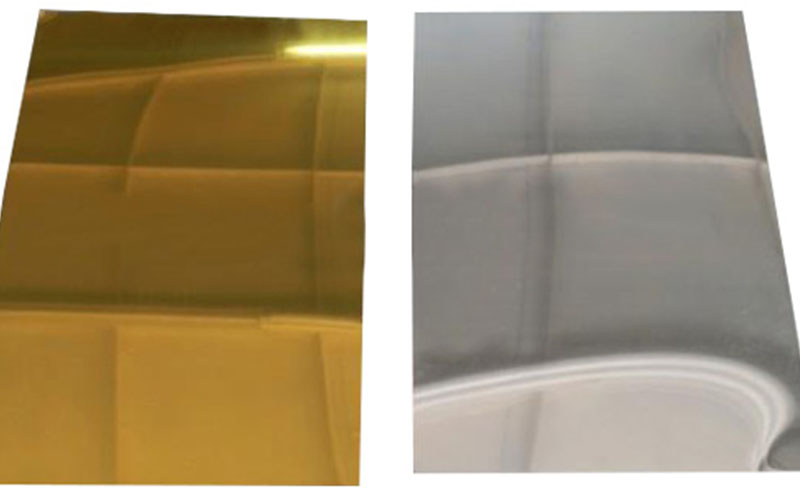

The aluminum mirror sheet has won increasing popularity as a decorative metal material. Functioning similar to a glass, mirror finish anodized aluminum sheet covers a much wider scope of application. In comparison with glass, it has the following advantages.

First, the mirror finish anodized aluminum sheet has a medium strength and a good tensile strength. This enables it to withstand complicated processes such as punching, bending and stretching without cracking, while glass breaks easily. The only possible way to process glass is to cut or drill it with an even harder diamond knife. Second, it’s appropriate for various surface treatment methods. Aluminum alloy sheets are adaptable to stable anodizing treatment, chemical polishing, fogging, chemical sand blasting, color coating and hole sealing. The anodised aluminum sheet is more resistant to corrosion and oxidizing. Third, it has a more extensive application scope, such as shells for electronic products (cell phones, digital cameras, MP4, laptops, mobile hard disc drives etc.), labels (bags, clothes, ornaments), reflective parts (lighting, solar power reflector), furniture, home appliances and so on. Fourth, light weight. Though aluminium and glass have similar densities (respectively 2.7 and 2.5), aluminum mirror sheets are usually lighter than glass mirrors, because aluminum sheets can be thinner than 1mm, but glass mirrors never reach such a small figure. Fifth, an aluminium mirror sheet can be embossed into a further product like a polishing aluminum diamond plate, which makes its usages wider.

Compared with glass, high reflectivity is not an advantage of mirror finish anodized aluminum sheet at all, because the former has a relatively higher reflectivity, mostly 90% and more.

Nydia

Nydia

Sales Manager

Sales Manager