What Decides Oxidation Resistance of Embossed Aluminum Plate

October 24, 2018

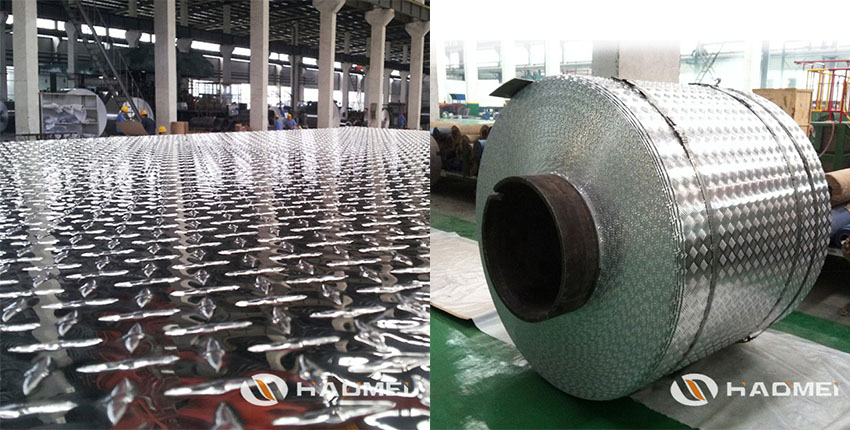

The oxidation resistance is regarded as a crucial element reflecting quality of embossed aluminum plates. It enables embossed aluminium plates to withstand severe exterior surroundings with high temperature, moisture or corrosive materials. All manufacturers declare that they supply embossed sheets of excellent oxidation resistance, yet superior plates are not so easy to be produced because their oxidation resistance depends upon several factors.

From a macro point of view, the oxidation resistance of embossed aluminum plates is up to the plates’ original grains, Cr distribution and content of other metals. The variation among original grains will lead to difference in property of the embossed aluminium sheet. Plates of small and uniform grains are likely to have excellent performance in oxidation resistance. The adding of other metal elements will make spinel structures come into being in an embossed plate. The structures help to stop Fe3 and Fe2 from spreading effectively, and thus eventually enhance the plate’s oxidation resistance. Take Si for example. The more its content there is, the more resistant is the plate against oxygen. Other elements, like Ti, have a similar function. Cr element reacts to oxygen and becomes chromic oxide that has strong oxidation resistance. Therefore, the more evenly distributed is Cr, the more uniform and stronger of an embossed aluminum plate’s oxidation resistance.

Nydia

Nydia

Sales Manager

Sales Manager