Aluminium Strip 2mm Used for Shutters

October 15, 2018

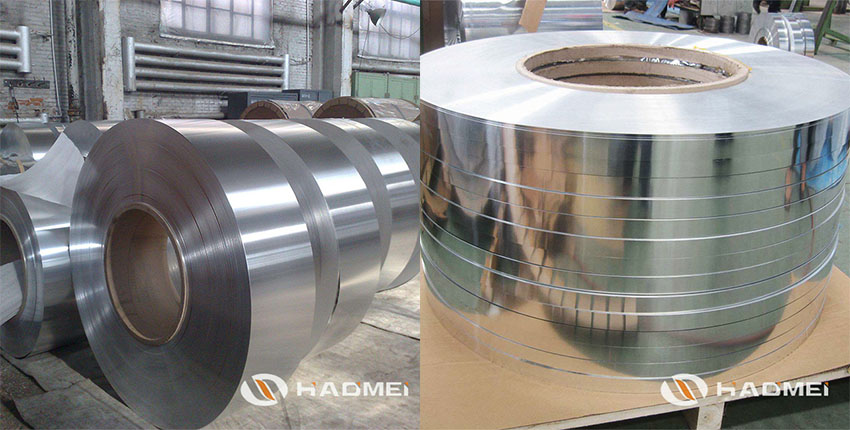

Aluminium strip 2mm belongs to the group of thick alu strip, because most aluminium strips are thinner than 1mm. Aluminium strip 2mm is mostly used for products requiring a certain strength for loading, such as aluminium eyelet for curtain tapes and shutters. Regular aluminum alloys for strip material include 1060, 1070, 1100, 3003, 5052 and 8011. Considering the fact that shutters have to bear kinds of natural forces like rain, wind, snow and sunshine, shutter manufacturers usually adopt 3003 or 5052 which is featured by strong corrosion resistance.

In comparison with other raw materials for shutters, aluminium strip 2mm has good hardness, excellent corrosion resistance but higher price. Plastics (mostly PVC) shutters only last around ten years, and they are likely to adsorb dusts because all plastic materials have the positive electron with them. Their advantage lies in price. Generally a plastic shutter costs as much as 40% less than an aluminum one. Plastic shutters have the lowest strength and shortest service life. Zinc-steel shutters are regarded to be the most cost effective of the three type, and they boasts the strongest hardness as well. They cost less than aluminium shutters as well. However, they show dissatisfying corrosion resistance in comparison with aluminium ones. Aluminium strip 2mm, like other aluminium materials, is endowed with a natural property against corrosive materials. Before it is processed into shutters, it gets anodized first, which proves to be a critical step strengthening its corrosion resistance. Anodized strips can be coated with paintings of PE or PVDF. These paintings not only provide pleasant colors for a shutter but also extend its service life substantially to at least thirty years.

Nydia

Nydia

Sales Manager

Sales Manager