General Introduction to Aluminium Strip

September 10, 2018

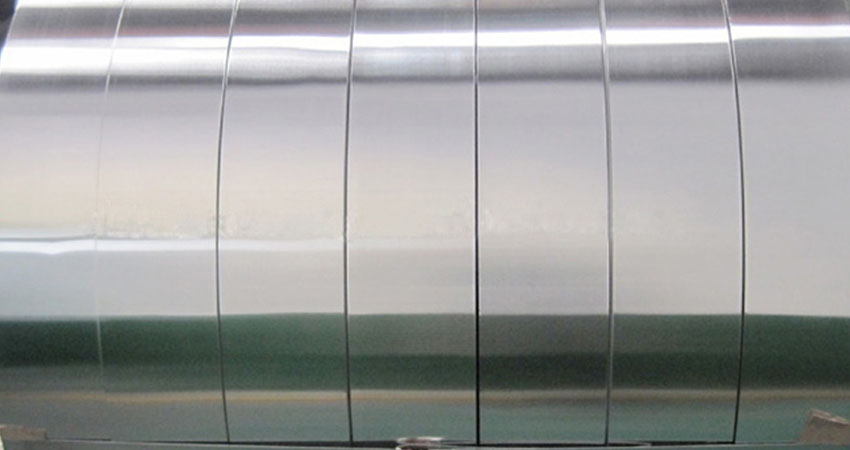

Aluminium strip refers to belt aluminum obtained by continuous rolling of aluminium ingots. The ingots are first processed into aluminum rolls of given thickness and width. The rolls are then slit into aluminium tapes of desired width like 1mm, 2mm, 3mm etc. Aluminium strip is among the most important raw materials for industrial production. The main processing device for it is the slitting machine which cuts aluminum rolls into required width and length. The machine was originally used for production of copper strip that is increasingly being replaced by aluminium strips with lighter weight and less cost.

Aluminium strip covers a wide range of application, including aluminum plastic composite pipes, electric and signal cable wrapping, transformer winding, heating machines, shutters etc. Some usages are of such large scales that they have become specialized commodity classifications, such as aluminium door strip, aluminium led strip etc. Similar to aluminium sheets, the strip falls on eight series, among which only 1xxx, 3xxx, 5xxx and 8xxx are frequently applied. 1xxx series is pure strip while others are alloy strip. The most widely used are 1060 and 1050 for transformers. In accordance with annealed conditions, there are soft aluminium strip (O state), half hard strip (H24) and hard strip (H18). There are also strips for special environments such as anti-corrosion strip.

Nydia

Nydia

Sales Manager

Sales Manager