Developing Prospects of Aluminium Slug for Tubes

April 26, 2018

Manufacturers of aluminium slug for tubes have been confronted with a tough challenge these years. Food industries, such as beverage and porridge etc, used to apply aluminium slug for tubes as raw material of cans. However, steel cans have been becoming more and more popular these years. Does it mean that aluminum slug have a negative prospect in these industries?

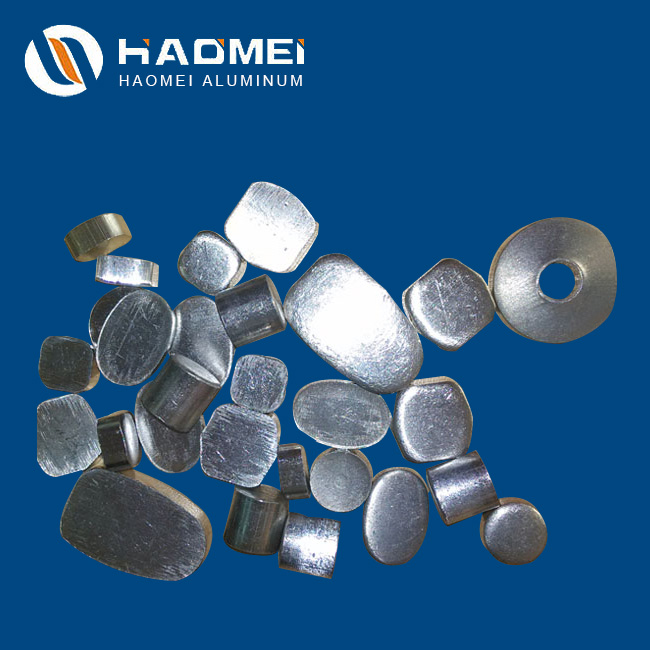

aluminium slug for tubes

To answer this question, we must figure out the reason for popularity of aluminium slug for tubes in the past. Aluminum shows better tensile strength and lighter weight than steel. Owing to backward technology it was more cost efficient to apply aluminum rather than steel. Now, however, advanced technology and manufacturing process improves greatly properties of steel cans which have similar performance with cans made of aluminum slug. Steel cans also overshadow aluminum ones in price. What’s more, people have been worried about safety problem of aluminum containers, because it’s believed that overdoing of aluminum does harm to people’s health. Steel has no such a problem and can spare them from that worry. Pessimistic experts predict that aluminium slug for tubes will be eventually replaced by steel as soon as the productivity of the latter becomes large enough.

Even though there is an element of truth in the view above, aluminium slug for tubes has an optimistic developing prospect. It’s still popular. Despite reduction of orders from food industry, its application in other industries like pharmaceutics and cosmetics remains considerable. Liquid medicine, facial cream and lipstick in aluminum tubes still take up a large market. Besides, it’s more environmental to use aluminum slug than steel slug. Although beverage manufacturers declare that steel is more applicable if judged environmentally, experts say it’s not the case at all. Reclamation depots refuse to take steel cans but welcome aluminum ones.

Nydia

Nydia

Sales Manager

Sales Manager